Equipment and materials

The drying equipment is manufactured by Incomac (Italy), with a single load of 2500 cubic meters of construction lumber.

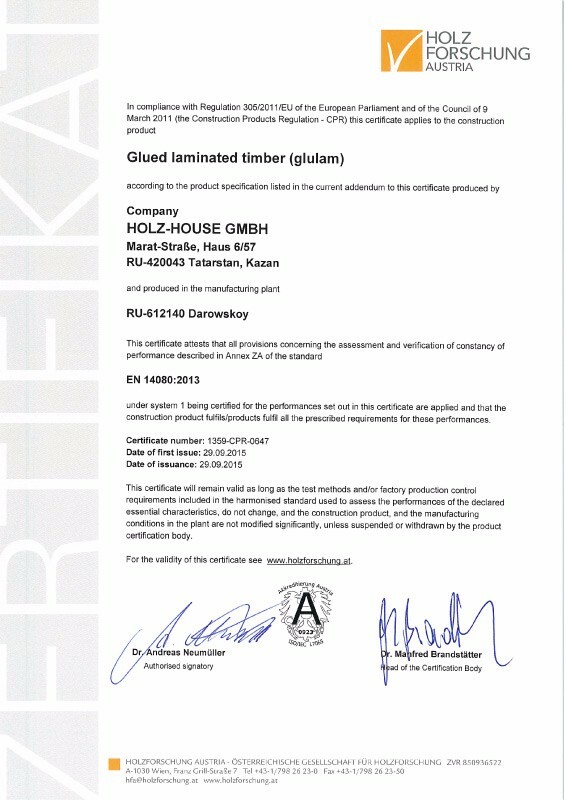

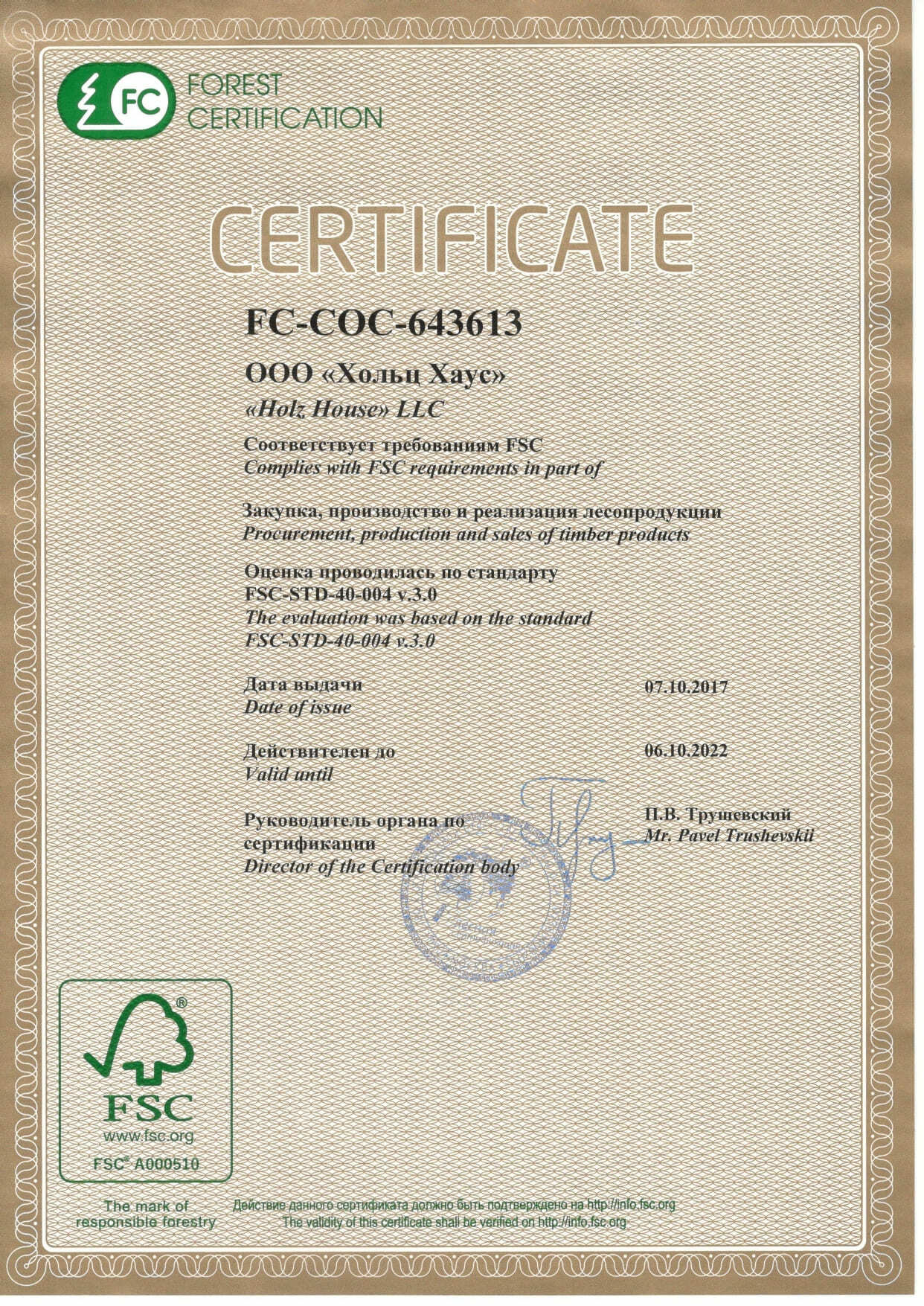

The glulam log in Holz House is made using advanced Austrian technologies. Experienced engineers and technologists of this country have designed workshops and developed technological processes. For woodworking, we use equipment from European manufacturers that design and supply equipment for industry leaders: Minda presses, Stromab CNC machines, Weinig slat production line and wood cutting line, Leadinec planing machines.

The climate control system is installed in woodworking shops: a constant level of temperature and humidity is maintained. There is also strict control over the moisture content of the incoming wood. Violation of these parameters automatically excludes building materials from the production chain.

Our adhesive products are characterized by strength, environmental friendliness, and durability. Safety corresponds to class E1. Adhesives of this class are used in the manufacture of children's furniture. These are products of the Akzo Nobel corporate group (Sweden). The technological process of gluing is based on the separate application of glue and hardener, which is important for the production of European quality log.

The cutting equipment for the manufacture of wooden parts of the house is equipped with a CNC, so the process takes place without human intervention, using a specialized computer program. The equipment produces parts in such a way that problems are eliminated during the subsequent assembly of the house. Each batch of oilcloth is tested in the company's own laboratory. The strength and quality of the adhesive joint is tested here by artificially creating extreme conditions that simulate the fifty-year service life of lumber, as well as the influence of temperature and humidity with indicators that are five times higher than the average.